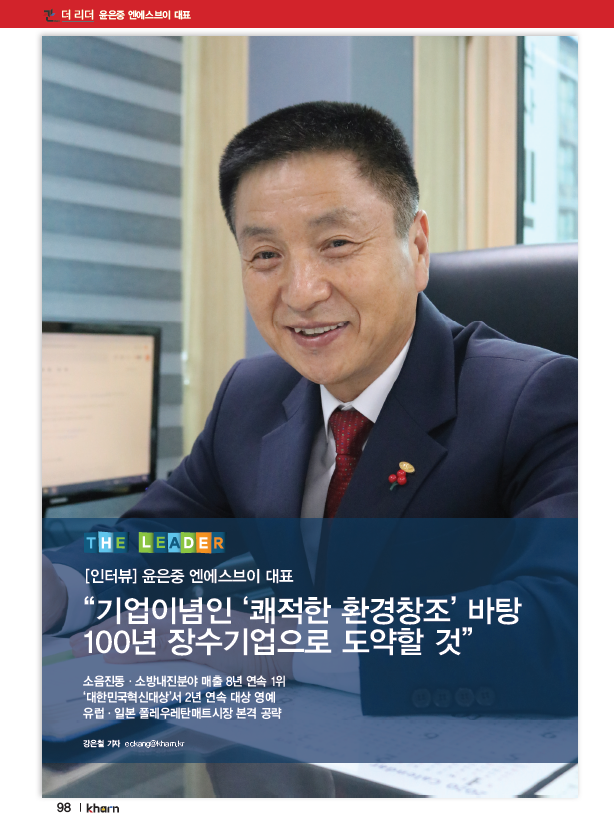

[Interview] Eunjoong Yoon, CEO of NSV

NSV

No. 1 in sales for noise, vibration and fire seismic for 8 consecutive years

Honored at the Korea Innovation Awards for the second year in a row

Tapping into the European and Japanese polyurethane mat market

(www.nsv.co.kr) is a soundproof and vibration-proof equipment company specializing in products and engineering that control noise, vibration shock, and earthquakes in construction and society at large. Founded in 1986 as Doojin Industries in Yangcheon-gu, Seoul, Korea, the company changed its name to NSV in 1994 and relocated to its current location in Namdong-gu, Incheon, Korea, and acquired KS standards in line with internationalization.

In 1996, the company launched the ISO9001 quality certification system and invested heavily in the development of differentiated products along with the establishment of a corporate research institute. As a result, overseas markets have gradually improved their awareness of Korean products and their quality, and the export market has been expanding.

BLAST VALVE installation inspection.

He was awarded the New Intellectual Award in 2000, the Minister of Trade, Industry and Energy Commendation, and the Seoktap Industrial Medal in recognition of his role as an export pioneer, and was awarded the Korea Innovation Grand Prize for the past two consecutive years in 2019 and 2020. We met with Mr. Eunjoong Yoon, CEO of NSV, who is growing as a leading company in the field that has acquired various certifications such as KC, KFI, and UL.

Who we are

Since its establishment on March 1, 1986, NSV has been dedicated to noise, vibration, and shock protection products for more than 30 years and has played a key role in the development of the construction industry. Recently, the company has been focusing its R&D capabilities on strengthening the seismic sector.

Our corporate philosophy is to create a pleasant environment. The company won the '2020 Korea Innovation Award' for its polyurethane mat product. Polyurethane mats are auxiliary materials used to block noise and vibration in buildings and various facilities. It is evaluated for its easy construction and excellent performance. It is widely used in building water supply and air conditioning facilities, subways, semiconductor and chemical factories, etc.

With the emergence of various skyscrapers, auxiliary facilities such as water supply and drainage, air conditioning, and electrical equipment are becoming larger and more powerful. The expansion of subways as a means of transportation in urban centers is also causing vibration and noise problems. As the level of public awareness rises, expectations for vibration and noise are increasing. Reducing vibration and noise has emerged as a factor that determines the quality of architecture.

Existing rubber soundproofing and dustproofing materials are limited by long construction periods, high costs, and low durability. In response, NSV has developed polyurethane mats that compensate for the shortcomings of rubber products. Polyurethane mats, which have good elasticity by forming a fine air layer inside the material, have the advantage of being able to be constructed in a relatively short period of time.

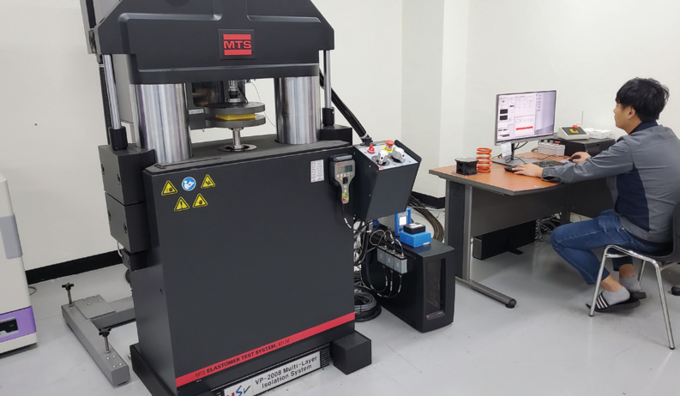

Experimental view of MTS dynamic characterization test equipment.

Last year, the company invested 5 billion won to introduce a mat analyzer that analyzes material changes found during the mat manufacturing process in order to strengthen its overseas markets. The company has been outsourcing the analysis of finished products to external testing laboratories, but will be able to increase efficiency and safety by inspecting them directly from the manufacturing process.

By providing innovative products and differentiated services, NSV has achieved the number one position in domestic sales for eight consecutive years in the field of noise and vibration prevention and fire seismic resistance, and won the grand prize for the VD-10 hybrid damper (2019) and PO-MAT polyurethane mat (2020) at the 'Korea Innovation Awards' organized by the Korean Standards Association for two consecutive years.

The status of the flagship product in Korea is

The occurrence of noise and vibration and complaints are complex and diverse in proportion to the development of the industry. Multifamily housing that reflects consumer demands is constructed with various materials and construction methods, and the architectural forms are complex and lightweight, so the noise and vibration environment is changing rapidly.

In work facilities, the use of equipment with increased convenience and the application of construction methods to save energy are in the mainstream, so the noise and vibration of the equipment itself have improved a lot, but the architectural environment in which the equipment is installed is worse due to more complaints and strengthened legal and regulatory standards.

The most commonly applied construction method is the raised floor method, which forms a structure that floats the floor, which is a source of noise and vibration, with a double floor, and NBS produces PO-MAT®, which uses polyurethane with high elasticity and resilience, as its main product. Since the IMF, the domestic construction trend has changed in many construction environments with the aim of new construction methods and cost reduction, and this is the product that accounts for the most sales.

Part of a PO-MAT automation facility.

In 2019, the company completed the PO-MAT automated production system and introduced the MTS dynamic characteristic performance test device to ensure its own reliability. In Korea, the jack-up system used to be the most popular double floor method, but now the PO-MAT method is recognized as a unique name.In terms of anti-vibration products, we are introducing precision vibration control products such as spring rubber pads (SRP) developed by combining spring and rubber characteristics, and passive and active air springs to the market. Seismic products for mechanical and electrical non-structural elements of special-class buildings in accordance with the KDS 41 17 00 Building Seismic Design Standards established in March 2019, and seismic products applied to fire pipes and equipment that have acquired KFI and UL recognition are steadily being developed and applied. Recently, we are also promoting joint technology development with Hyundai Heavy Industries to localize fluid silencers for warships.

SHOCK MOUNT installation check.

For the current state of the flagship product market, seePolyurethane anti-vibration mats are a product that has gained a lot of import substitution effect by securing foaming technology and manufacturing facilities through joint research with the Industrialization Department of the Ministry of Trade, Industry and Energy's Institute of Technology and Standards to locally develop mats using polymer chemicals from advanced European countries.

PO-MAT boasts sales of more than 30 billion won in the 20 years since its development and is applied to machine rooms, large-space sports facilities, special facility structures, and foundations and sides of buildings adjacent to subways in various buildings in Korea, and demand is expected to rise every year as awareness of vibration and structural noise increases.

In addition, the hybrid damper is a product that can secure the stability of the system by controlling the vibration displacement transmitted to the pipe during equipment operation. Since it can control the piping from breaking or deviating without interrupting the operation of the existing piping, it can solve vibration problems that occur in areas where it is difficult to stop the operation of the system, such as petrochemical complexes, seawater desalination facilities, nuclear power plants, semiconductor facilities, etc.

Differentiate yourself from the competition

In August 2018, the company built and completed its headquarters and factory in Namdong Industrial Complex, Incheon, with a scale of 1 basement floor to 3 floors above ground, and installed automated production facilities for polyurethane mats with a total length of 30 meters on the third floor. It also built a system of mass production facilities such as rubber molding machines, 450-ton power presses, semi-automated robots, and a smart factory system.

In particular, the new production facility for polyurethane mats has enabled the company to produce 1,000 mats per day, five times more than the previous production capacity, and the introduction of a mat analyzer that analyzes material changes found during the manufacturing process has increased efficiency and safety by directly inspecting all manufacturing processes.

Unlike conventional hydraulic and mechanical dampers, hybrid dampers have virtually no chance of leakage and an unlimited service life. They are also economical due to their low maintenance. The new products developed by the institute are promoted to architectural firms and building facility design offices, and responsible design is carried out through technical support to ensure the reliability of the design, and information is transmitted to the sales of construction companies, leading to orders.

Nsv has won the 'Korea Innovation Award' for two consecutive years.

The projects designed by NSV have been meticulously supported from the order to the completion test and operation, and have received a lot of trust, leading to repurchase. We will work harder to ensure that our products are reflected in future designs. We are grateful to those who helped us a lot by borrowing the ground.

NSV signed a joint development agreement with Hyundai Heavy Industries to develop a fluid silencer.

Key wins and installations are listed in the

The most iconic building is the Lotte World Tower in Jamsil, but this year, the construction industry was severely affected by the COVID-19 pandemic, which greatly affected orders. Other projects include Acro Seoul Forest and Daejeon Expo Science Complex, which are mainly residential, retail, and business facilities. In particular, noise reduction devices, double flooring systems, and anti-vibration products, as well as seismic braces for fire pipes, were installed in apartment buildings such as the new construction of the urban environment maintenance project in the 4th district around the Yongsan International Building.

In the defense industry, the company supplies passive and active isolators for precision equipment control in semiconductor sites and manufactures and delivers vent silencers to reduce the noise of high-pressure jet streams in plants.In addition, in the defense industry, the company has achieved more than 13 billion won in orders by designing, delivering, and constructing shock mitigation, blast valves, and blast doors in collaboration with overseas structural design offices such as the Pyeongtaek U.S. Korean Command Operations Center, the U.S.-ROK Allied Operations Center, and the U.S. 2nd Division.

This year's business goals and mid- to long-term vision are

This year's sales target is 33 billion won, and all employees are doing their best to be proactive in their work, even in the face of difficult business conditions due to the sudden COVID-19 outbreak in the first half of the year. Achieving the annual sales target is the short-term goal of all employees at NBS.

The mid- to long-term goal is to develop the Japanese polyurethane mat sales market by signing a polyurethane mat technology agreement with Kurashiki, a Japanese company specializing in dustproofing, and to compete with Austria's Getzner, which accounts for 70% of the world's polyurethane mat market, to create polyurethane mats that are recognized in the Japanese and European markets.

If you have any final thoughts

I believe that there is no greater growth engine than having employees moving in the same direction toward the same vision and goals. There are only about 10 companies in Korea that have been around for more than 100 years. We will strive to become a responsible company that serves society by being grateful every day to become a company that can continue for 100 years by recalling the founding spirit of NSV, which is to value talent, fulfill responsibilities for customers and employees through continuous innovation, and contribute to society by developing the company.

Source :https://www.kharn.kr/news/article.html?no=14223